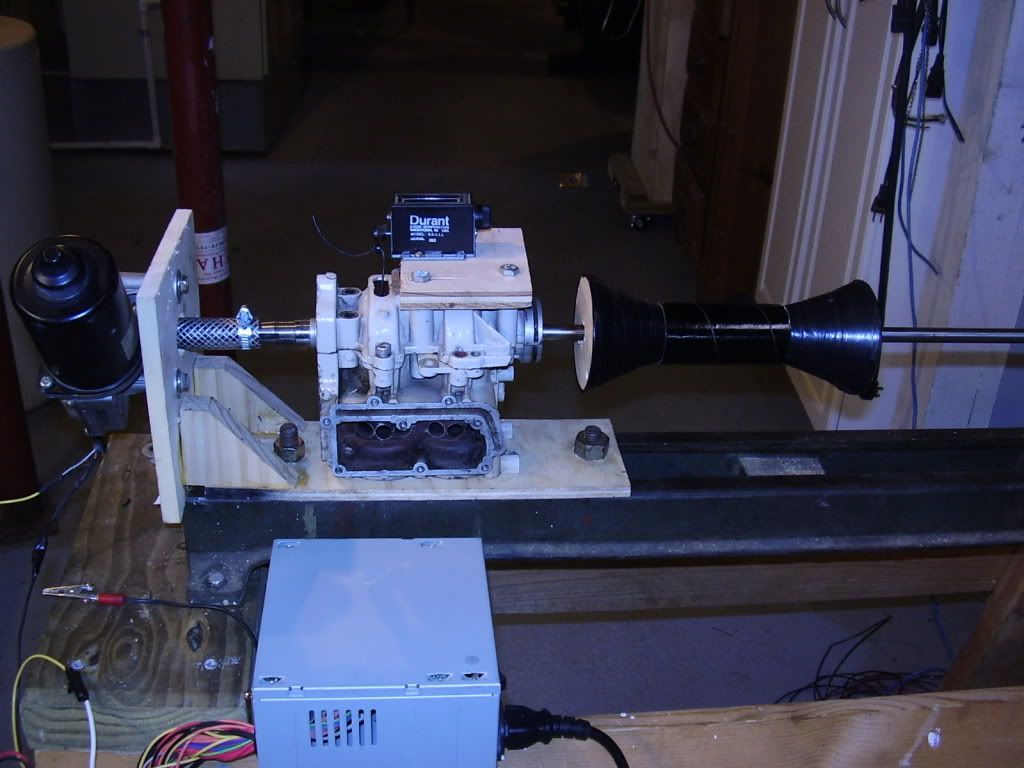

I am ready to start building my coils. I've done a few test runs using hard tubes and fishing line. I built a coil machine out of a 1947 Evinrude 2 hp crank case powered by BMW wiper motor. It works well. My question is what exactly do the specs mean when they say the coils are 150 turns TAPPED at 50 turns? I see the schematic where L1, L4 and L5 "tapped" but what does this connection look like? Do you just bring a hole through the tubing and connect the tapping wire to the coil at 50 turns?

Building Coils

Without having seeing the physical coil, I'd say after 50 turns you could just pull the coil wire itself through a hole and solder it to a lug, then continue turning the final 100. I.e., no need to cut the coil wire or use another piece of wire for the tap.

yes, "after 50 turns, poke a hole and pull the wire thru and connect it to a lug- then keep winding 100 more turns." I'd really recommend just using a hand crank, especially for winding the smaller osc coils. better control- (maybe a converted sewing machine motor geared way down /with rheostat for speed control )

I see a remake of a Classic '50's sci fi movie in which the 50 foot woman plays her own scary music on a 50 foot tube theremin...Which will, of course take as much power to run as a small city....Dewster may have to help design some speakers big enough to handle this job..;-)

You must be logged in to post a reply. Please log in or register for a new account.